Bioresorbable labels and

packaging materials

Sustainable product packaging has gained a lot of

interest in the last 2 years, especially in the food industry.

This is due to the fact, that during a walk through the supermarket,

it is quickly apparent that fresh as well as durable

products are often packed in extensive packaging.

When does packaging

make sense?

Packaging materials generally have the purpose of protecting the product. Not only from damage, but also from dirt or bacteria. The hygiene aspect is particularly important for fresh products. For example, freshly packed meat, cheese, fruit or vegetables. Here the packaging protects in particular against the accumulation of bacteria. The product remains fresh and has a longer shelf life thanks to the packaging. In some cases, products are packaged in a protective atmosphere. This extends the shelf life of products and allows fresh meat to have a shelf life of up to 14 days. In comparison, meat from the counter must be consumed within 1-2 days. Minced meat even on the same day.

When does packaging

make little sense?

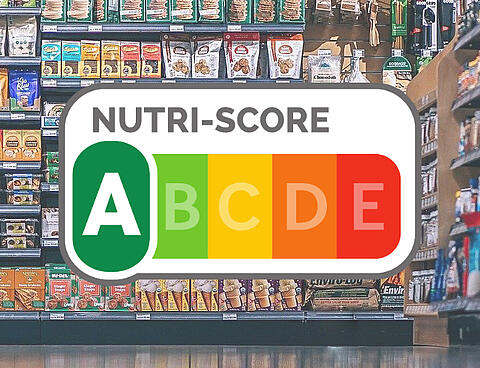

The keyword is "Point of Sales". Also called POS. The packaging industry regularly comes up with new designs, shapes and colours for product packaging in order to convince the consumer of a product in the best possible way. Because this increases the purchasing power for the brand. The more appealing and unique the product appears on the outside, the more likely it is to convince the critical end customer. Unfortunately, this often conflicts with the sustainability of packaging. Because often the great packaging shapes and colours are also the ones that generate the most plastic waste.

In recent years, the way consumers think has changed. Many consumers now pay more attention to minimalist packaging rather than the appearance of a package. Packaging must protect the product. Nothing more.

Supermarkets rethink their stock

Supermarkets across Europe have clearly already made their statements on more sustainability in 2019. For example, almost all large supermarkets and discounters are now avoiding packaging for fruits and vegetables that do not have to be protected against damage by packaging.

Aldi and other discounters are even going so far as to reduce their use of plastic for fresh produce by 30% by 2025. This is to be achieved primarily through the use of compostable materials.

The industry is moving along

The promises of supermarkets and discounters can only be realized, if the packaging industry keeps up and develops new materials faster than planned. For example, bioresorbable plastics. Here, the big challenge is to find materials that protect the product to the same extent in terms of durability and damage as conventional packaging. It is also important to consider not only bioresorbable or compostable packaging but also the label on the packaging. Both are in direct contact and are not disposed of separately. Therefore, the compostable packaging is only as good as its compostable label. For both packaging materials and labels, there are now initial approaches that are heading in the right direction and at least make industrial compostability possible. Pulp is used, for example on a wood or rice paper basis, which is processed into packaging and label materials in various stages.The show stopper however could be the price, because these new types of packaging and label technologies make products more expensive. Compostable packaging and labels are often 3-4 times more expensive than conventional materials.

Digitisation in food production

Digitisation puts classic machine parameters such as speed and modularity in the shade as digital machine functions allow far more savings potential to be realised.

Find out in our new post about the technologies that digitalisation brings with it.