OPC UA,

the communication interface for industry 4.0

A uniform interface for communication between machines

An important basis for the successful introduction of Industry 4.0 is the manufacturer and platform independent exchange of data in production. For this purpose, the open interface standard OPC UA has meanwhile established itself worldwide. OPC UA stands for "Open Platform Communication Unified Architecture". It enables mechanical and plant engineering companies to digitally network their production. Machines and systems can thus be integrated as required via Plug & Work - regardless of the manufacturer of the machines and components in production.

However, with OPC UA "only" the grammar of the language for machine-to-machine communication is set. The core work of manufacturers and associations in the OPC UA world is to standardize the vocabulary of the functional description of the machine worlds. OPC UA Companion Specifications is the technical term for these standards.

Open Source is the interface solution

Meanwhile, a large number of different branches of the mechanical engineering industry are working on the implementation of the Companion Specifications for their area or have already completed and published them. The openness of the approach - open source - offers all interested companies the chance to participate and implement them for their products.

In 2017, twelve of the most important German scale manufacturers have already decided to develop a standardized OPC UA interface for their industry with the support of the VDMA.

This is an important measure, because in Germany alone there are 150 different types of equipment from high-precision laboratory scales to rugged truck scales - with a correspondingly large number of interfaces that are still in use today. Scales are used in many areas and practically along the entire value-added chain to optimize processes, increase productivity, but also to comply with legal regulations.

To perform these tasks, scales must be able to communicate with various systems in the value chain, not only with upstream and downstream systems along the horizontal communication level with other machines, but especially with MES or ERP systems along the vertical communication level.

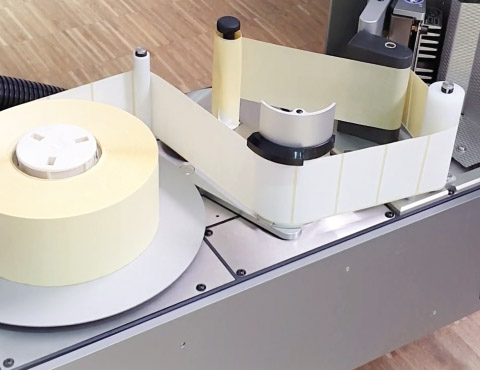

OPC UA in weighing and labeling technology

In the field of weighing technology in the food industry or industrial price labelling systems, the demand for online integration and networking of such systems had been present for a long time and was also implemented with manufacturer-specific solutions.

Finally, the scale as a metrological measuring instrument has a key function within an entire process chain in food production, because it knows the exact status of all customer orders by individually weighing each package and can forward this information to the production and customer database systems. This was previously implemented with proprietary manufacturer-dependent interfaces.

With the help of OPC UA, this will now be possible for all systems along a production line without the need for complex customer-specific solutions.

With the implementation of the OPC UA Companion Specification, the wish of many customers to be able to call up the real-time status of production remotely and intervene before a line comes to a standstill can be fulfilled technologically, in line with the guiding principle of Industry 4.0.

Digitisation in food production

Digitisation puts classic machine parameters such as speed and modularity in the shade as digital machine functions allow far more savings potential to be realised.

Find out in our new post about the technologies that digitalisation brings with it.