Food safety as a focus topic

for packaging manufacturers in the food industry

The Corona crisis and Brexit still bring a lot of uncertainty. New European regulations are additionally having a major impact on the food industry. Everyone in this industry has to deal with one challenge or another. In addition, high demands are constantly being placed on the ability of your own employees to change.

As a packaging manufacturer in the food industry, you have to consider the demands made, especially on food safety. Not only because of the legal requirements by the EU, but rather because the consumer expects it. One more reason to pay more attention to food safety in 2021.

Focus topic: Food saftey

As a producer of packaging for fresh meat, fish or meat / fish substitutes for retail, a number of measures can be taken to ensure food safety.

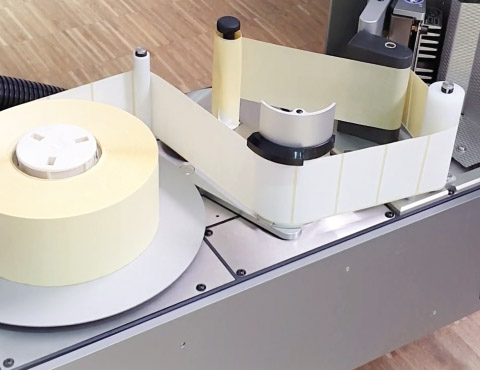

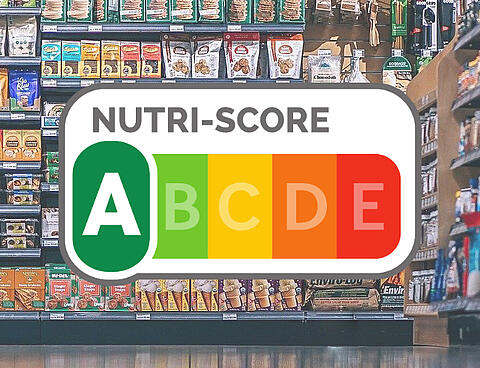

First, ensure that there is a central database for the processing of all raw materials used. If this database also contains recipes and further information, a direct link should be made between this data and an automatic print & apply system for labels. This will ensure that the correct declaration is made on the correct label on the correct package. Incorrectly declared allergens are one of the main reasons for recalls and thus a breach of food safety. Especially for people with an allergy or food intolerance this is fatal and the trader respectively the producer is held accountable.

The best-before date (BBD), for example, can also be applied automatically. This avoids a recall due to an incorrectly labelled best-before date. Practically all weighing and labelling machines can automatically generate a best-before date. The information for this is based on a central database that contains the necessary information per product and per package. These are automatically used together with the current production date to determine the correct best-before date and apply it to the label.

Furthermore, metal detection is already a standard to detect and remove metal contamination in the process. With decreasing prices and better availability of radiographic systems, there is the additional possibility to detect various other contaminants besides metals with radiography.

As a final step, a vision system can be installed for inspection. Here, one or more cameras inspect the packaging by analysing a photo of each package against set reference values. In this way, the vision system can determine - within its own limits - whether the packaging is correct and, above all, whether the right information and the right product are in the right place on the right label.

The automation of weighing, labelling and inspection thus increases the food safety of fresh food and permanently avoids image damage and recall costs.

Digitisation in food production

Digitisation puts classic machine parameters such as speed and modularity in the shade as digital machine functions allow far more savings potential to be realised.

Find out in our new post about the technologies that digitalisation brings with it.