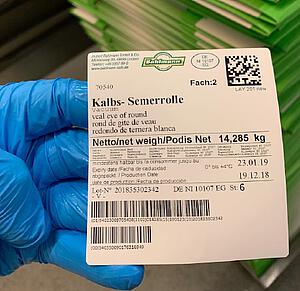

The label on a package is an information carrier for the end consumer. Not only the weight, price and expiry date are displayed. Rather, it gives the consumer certainty as to the origin of the product and the processed ingredients. Studies have shown that end consumers attach greater importance to a comprehensive product declaration since several years. The keywords "Healthy Food", "Clean Eating" as well as "From Farm to Fork" are decisive factors for a generation that is interested in the product and does not only opt for a product from a cost point of view. The basis for this is individual product labelling, which leads to small batch sizes up to batch size 1, as is the case at Hubert Bahlmann KG, manufacturer of veal products.

For Hubert Bahlmann, traceability from birth to cutting of veal products is a unique selling point. All relevant origin information is stored centrally in a database. The information from this database will be used to be printed on the label. The aim is to create transparency about the product and to focus on sustainability and regionality.

But how to control individual product labelling for different product types and product geometries?

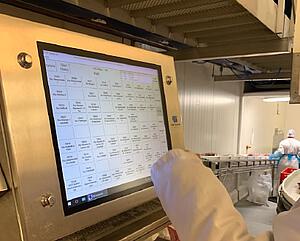

At Bahlmann, the product feed is visually checked by the employee on the conveyor belt and selected directly via the machine terminal. A visual product segmentation via a camera system is also possible. The product information stored in a database is then forwarded to the labeling system and label printing starts in real time. All this with small product batches up to batch size 1 and speeds of up to 100 packs per minute.

Light barriers along the conveyor elements measure the start and end lengths of each product and thus define the perfect labelling position. No matter whether it is a meat cut of 15 cm or 70 cm.

Bahlmann declares the complete origin information legibly for the end consumer on each label and additionally stores this information in individual barcodes, which are also printed on the label. For example, information on the place of birth, slaughter and cutting. Together with classic barcodes for batch numbers, weight and price information, up to 3 different barcodes can be printed on a label. In order to guarantee the readability of the barcodes for the retail markets and to avoid recalls, each product is checked by an integrated scanner directly after the labelling process. If a barcode is not readable, the product is immediately rejected.

SIf all barcode information is readable, the products are automatically sorted into sorting units. On the one hand, products are sorted according individual customers; on the other hand, products are also sorted by product type. The employee recognizes on the display of each sorting unit how many products are still missing to complete an order and automatically receives the total label for the container for each completed order. Thus, the perfectly labelled meat product with all consumer-relevant information reaches the wholesale or retail trade within a very short time and is perfectly labelled.

Service: +49 203 30540 | info@espera.com