ESPERA labelling systems and software solutions designed to meet the requirements of the meat processing / packaging industry. Learn more about our applications, such as automated product traceability "From Farm to Fork".

The meat company Boni Vers Ambacht, Netherlands is convinced of the ESPERA technology due to different reasons. On the one hand the machine performance and reliability, on the other hand the soft facts of the ESPERA service and support via the ESPERA team. Learn more within this report about latest functions and features of the 7000 series of automatic weighing & labelling systems and its advantages.

The meat company Boni Vers Ambacht in Nijkerk / Netherlands and ESPERA have known each other for a long time, but their collaboration really kicked off when important governmental regulatory changes in the declaration of products were expected.

In 2008, Gerrit van Zalk was the Fresh Meat Category Manager at Boni. In that year, he approached the Boni management with the idea of adding a centralized butchery division. The green light for this was given in 2010. Van Zalk´s target was a unique approach: maintain and improve the quality of fresh meat products in the Boni supermarket stores and managing all via an own supply chain. This enables the full control of the process from farm to fork.

Every day, Boni Vers Ambacht supplies its 45 Boni supermarkets across the Netherlands with fresh meat. The production is based on orders. The stores send in their orders at 08:30am and by 4:30pm everything is ready to be transported to the supermarkets.

The last years an additional business model came up. With the supply of the online supermarket Picnic! In total, more than 70 tons of meat find their way to the supermarkets and the Picnic delivery vans every week.

Van Zalk: "Our approach, with fixed suppliers, fixed prices, extra focus on quality, sustainability, and animal welfare is an investment, but this form of chain control allows us to increase our cost efficiency. We want to keep the purchasing of meat affordable for a wider public while, at the same time, making sure that both the farmer and the retailer can earn their margin".

According to governmental requirements for in the declaration of food products, the labels need to include information on allergens and nutritions in a specific typography. This requirement could not be realized by the current supplier of labelling systems. Furthermore, the function of the ESPERA machines to work also in fixed weight mode is an outstanding advantage other suppliers can´t fulfill. At that point Boni Vers Ambacht decided to renew their lines with ESPERA.

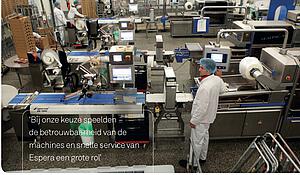

Boni started with a first line for trial of ESPERA as a new supplier. The results were great and absolutely convincing. In the meantime, Boni Vers Ambacht is installing its fourth ESPERA machine. The reliability of the machines and the excellent and fast service ESPERA provides, played a major role in the choice for ESPERA.

Smaller maintenance cases Boni Vers Amacht is able to fix by their own team. ESPERA offers special customer trainings. In case if any issue can´t be fixed by the Boni team, the ESPERA service center can react quickly, due to its global presence. Furthermore, immediate service support via remote control is at any time available.

A quick reaction time of the machine suppliers is vital for Boni. They can´t keep any products on stock. Everything is produced fresh. And the stores open at 8am every day. So, the supply chain for the shops has to move on.

But what are the real facts that create efficiency by using the ESPERA technology?

All together this leads to an efficiency improvement of the labelling process of 30%.

Service: +49 203 30540 | info@espera.com