Our unique and modular application concept

„Switch & Go“

Every product requires its individual treatment. Labelling of sensitive products in flow pack packages,

such as strawberries, require another label application technology than meat products in tray packaging.

To meet this demands of the fresh food industry we created a fully new appplicator technology callled "Switch & Go".

Select out of 3 different application systems depending on the product requirements

Our unique and modular application concept

„Switch & Go“

Every product requires its individual treatment. Labelling of sensitive products in flow pack packages,

such as strawberries, require another label application technology than meat products in tray packaging.

To meet this demands of the fresh food industry we created a fully new appplicator technology callled "Switch & Go".

Select out of 3 different application systems depending on the product requirements

What makes our application technology unique?

We focus on the demands of our customers

in fresh food industry and developped in cooperation

with our customers the perfect fit technology.

What makes our application technology unique?

WWe focus on the demands of our customers

in fresh food industry and developped in cooperation

with our customers the perfect fit technology.

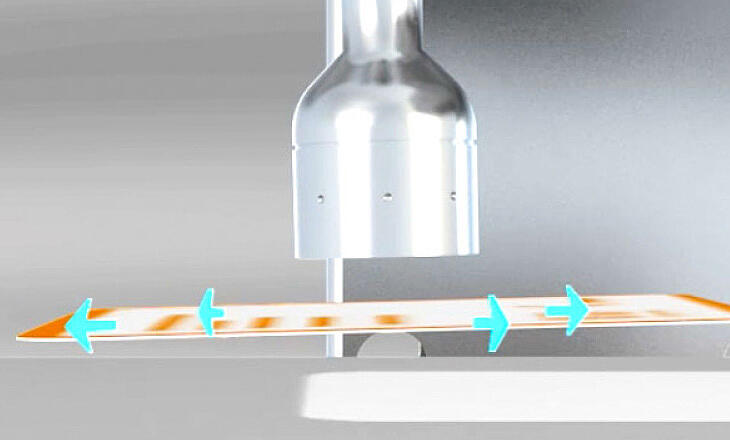

When does an air blow application make sense and how does this technology work?

Sensitive products can be labelled smoothely with an air blow label application. But don´t forget to consider the accuracy of the label placement. Conventional manufacturers offer air blow label applications directly from the printing unit. For this, the labels are blown from the very top position of the printer to the product packages. Often the label has to be blown a distance of 100-150 mm just by a conventional air blow. The reult is, that the label ends up everywhere but not correctly on the package.

We have the solution!

Our applicator is moving downwoard with the label from the printer to the package. 8-10 mm above the package, the applicator is releasing an airblow and applying the label smoothely. This leads to a perfect labelling position and avoids wrong label placement or no label placement and is fully different to conventional air blow label applications.

Video Luftdruckapplikation mit ESPERA.