Label placement at its best with the unique 3D Camera

Independet from the product shape, size or geometry –

we place your label fully automatic always at the perfect position.

Increase your quality process and eliminate worse or wrong labelled products!

Label placement at its best with the unique 3D Camera

Independet from the product shape, size or geometry –

we place your label fully automatic always at the perfect position.

Increase your quality process and eliminate worse or wrong labelled products!

Independent of the product shape

or package type - the perfect solution for...

… various product geometries, e.g. flow wrapped packages

Precise labelling of naturally grown products, such as fruit and vegetables in flow pack packages is always a challenge. Due to the huge variety of product shapes, not every fruit or vegetable product can be labelled at the correct position. The 3D Camera detects the shape of fruit product or package and places the label fully accuarte at the perfect position. For a 100% label placement and full label readability.

… irregular product geometries, e.g. natural products

Full chicken in shrink packages, either if they are frozen or refrigigated, are always a challenge with regards to label placment. The 3D camera detects the shape of the chicken and calculates fully automatically the perfect labelling position. For a 100% label placement to avoid non-labelled prducts reaching the retail industry and to guarantee a perfect redability of label information for the consumer.

… irregular product size and positioning in skin- and stretch packages

The trend of skin packages lead to new challenges with regards to product labelling. Depending on the size and position of a product, packed in a skin packge, the perfect labelling position varies from product to product. With the 3D camera this can be handled fully automatically. The camera detects the product position within the skin pack and detects the perfect labelling position. Printers are getting adjusted autoamtically according to the calculated position.

… labelling of rising / falling edges

How to label a cheese triangale always at the correc position? How to guarantee a 100% perfect labelled triangle of cheese? With the unique 3D camera this is possible. Without any manual printer adjustments. Full automatic the camera detects the geometry of each cheese triangle running over a labelling line and defines the perfect labelling position. All settings for the printer and applicator are done automatically for a full zero downtime concept and a 100% perfect product labelling.

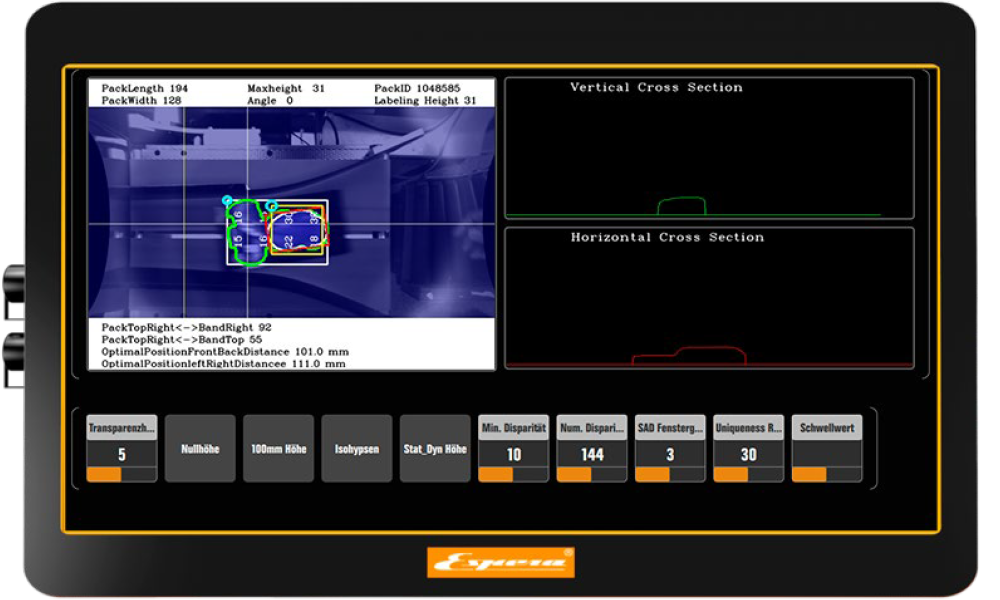

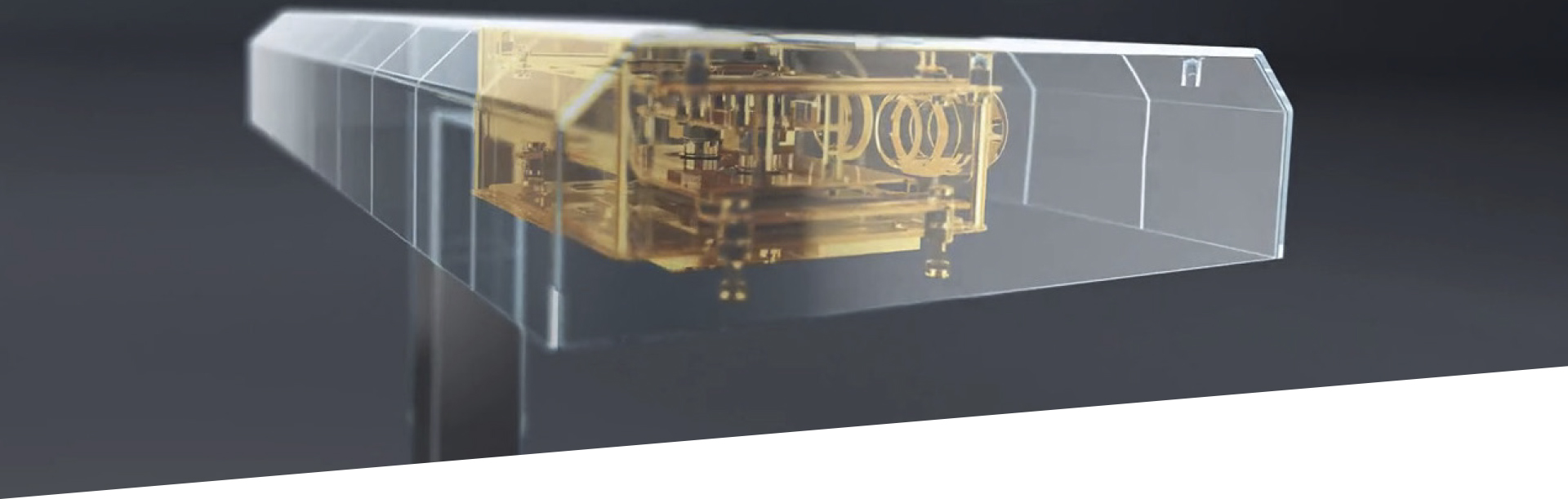

How does a 3D cam for product detection work?

A combination of camera technology and intelligent software solutions enable

an in-line product and package geometry detection.

How does a 3D cam for product detection work?

A combination of camera technology and intelligent software solutions enable

an in-line product and package geometry detection.

You want a 100% labelling quality control?

The ESPERA 3D Camera can realize it.

Furthermore, with this technology packaging data are automatically stored within the packaging program.

So package data don´t need to be set by the production team per each product.

The 3D camera can do this automatically which is time saving and failure preventive.